Metal-Projects | Production | Industrial Applications of Additive Manufacturing

Share

One of the preferred methods for producing industrial items and equipment is additive manufacturing because of how quickly, creatively, and simply it can be done. The manufacturing of equipment and tools used in the manufacture of other items is included in the category of industrial goods.

This industry often uses traditional production techniques like CNC machining, which are expensive and time-consuming. 3D printing can supplement or replace conventional machining in this sector to cut costs and time.

Why use 3D printing for commercial products?

Regardless of the industry, 3D printing is without a doubt the best technology available for prototyping. The production of industrial goods requires significant investment in research and development, where the products go through numerous revisions from the initial design stage to the final manufacturing stage.

The procedure must be quick and inexpensive to reduce costs and meet market demand. Rapid prototyping, often known as 3D printing, is perfect for this.

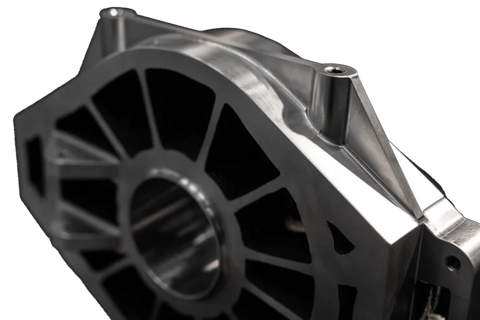

Components that are challenging to manufacture using conventional manufacturing procedures can be produced using additive manufacturing with less design constraints. By enabling the addition of improved features like decreased weight (via lattice structures) and complicated geometries that are not attainable through conventional techniques, this design freedom opens the door for innovation.

New AM technologies may also progressively create printed items made of many materials that have unique characteristics like electrical conductivity and varied strength. Future machines will be safer, lighter, quicker, and more productive thanks in large part to these AM methods.

Another benefit is the ease with which new and used devices can be printed to the required volume using a variety of 3D printing materials directly from a manufacturer's digital inventory or a customer's CAD model. This changes the supply chain and enables producers to quickly satisfy demand.

Industrial applications with 3D printing

Tooling, which entails the printing of lightweight and robust jigs, fixtures, and gauges, is one of the main industrial applications of 3D printing. Metal 3D printing may be used to produce injection molding dies with ease. Making a die takes a lot of work and design iterations. However, because 3D printing makes it possible to create complicated designs, traditional cooling patterns for molds can be replaced with modern cooling channels, boosting the efficiency of the mold's cooling system.

Both metal and polymer 3D printing have already made a name for themselves in the industry. Due to the shortened lead times and low cost of prototype, many industries, like aerospace and the automobile, have already begun employing additive manufacturing in their operations. Porsche, a leading automaker, has begun 3D printing engine piston production.

3d metal printed pistons (source: Porsche)

3d metal printed pistons (source: Porsche)With the aid of CAD, drawings for practically all parts may be digitally copied and kept on a computer hard drive, doing away with the need to keep an inventory. A spare part might be printed when needed with the aid of 3D printing. A simple supply of 3D printed components and spare parts will be available thanks to providers opening up new facilities in response to the technology's accessibility.

Even obsolete parts can be recreated to meet specifications using reverse engineering techniques based on digital images of working components. Older designs might have a second chance at life, and on the flip side, antique car spare components are simple to make.

Conclusion

At Metal-Projects, we offer fast, reliable, and highly accurate 3D printing services for thermoplastics, elastomers, and metals that are of immense benefit to industrial companies. We also offer various post-processing operations to ensure the utmost quality.

Regardless of quantity, precision, complexity, and required delivery time, we always have the manufacturing capacity to deliver. Head on to our quoting platform to upload your models and receive multiple offers, absolutely free.