Metal-Projects | Production | Accelerating Hardware Prototyping for Startups and Small Companies

Share

Startups need to find strategies to simplify and hasten product development as products become more complicated. The industry is transforming as a result of open-source microcontrollers and quick hardware prototyping. This article gives a brief overview of the advantages, goods, and production-related methods you can employ to give smaller firms the means to compete in the electronics market.

Benefits of Hardware Product Prototyping

Software, power, and mechanical components are only a few of the technical techniques that go into designing an electronic device. By prototyping products before moving them into production, companies logically hope to save money, time, improve their brand image, and boost quality. In later stages of production, prototypes can help discover errors and cut costs. They offer a mechanism to iterate, fail quickly, and evolve a product.

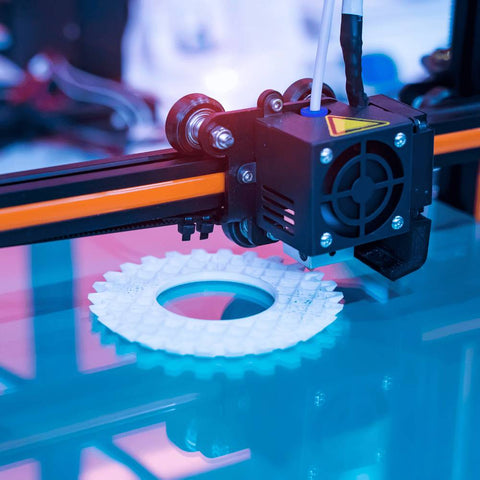

Prototyping hardware products gives businesses a greater grasp of how end customers interact with their products in actual settings and helps them identify and resolve technical problems. It also makes a market placement prediction for a product. For instance, working electronics is not recommended at high temperatures. A functional prototype can discover that the hardware is overheating or that a printed circuit board has a hot spot (PCB). The issue might be resolved by adding vents to the hardware design. Companies can move swiftly from one iteration to the next with small production runs thanks to the availability of fast prototyping and digital manufacturing techniques like CNC machining, injection molding, 3D printing, and sheet metal fabrication.

IoT and connected hardware prototype products

Companies frequently link one-off purchases or low volume with high costs or high minimum order quantities. The cost and lead times involved with custom PCBs and software are more challenging. The integration of open-source microcontrollers in prototype items, digital manufacturing, and unconventional procedures with cloud services lowers costs and lowers volume requirements, making prototyping more affordable for all businesses, including tiny startups. Here are a few illustrations of hardware platforms and services:

Particle: incorporates a platform-as-a-service into each of its products for remote management and software application integration; modules and gateways offer an Internet of Things (IoT) prototype solution right out of the box.

Raspberry Pi: A reasonably priced, credit-card-sized computer that connects to a computer monitor or TV and operates with a regular keyboard and mouse; this resourceful small computer allows users of all ages to experiment with programming in languages like Scratch and Python.

Arduino: a corporation, initiative, and user group that produces single-board microcontrollers and microcontroller kits for the construction of digital devices using open-source hardware and software.

What to Take Into Account When Selecting a Prototyping Process

Designing an experiment is a process that is similar to choosing which products, methods, or materials to employ for prototyping. Although not all prototyping processes may be required in the development process, many prototypes are frequently required to prove various concepts. You should first have a strategy for what each prototype is meant to accomplish. Define in advance the relative importance of each iteration's material, surface finish, and functionality.

The most valuable—and capable—product will reach the market if you locate a provider with competent engineers to advise you through the process. Many prototyping facilities can offer unconventional techniques and digital technologies. For instance, 3D printed parts can be produced quickly. Can the printer, however, satisfy the requirements of the final process if the production pieces are going to be machined or molded? Prototyping knowledge is essential because of this.

Types of Prototypes

Prototypes are frequently described in terms of form, fit, and function. The following types of prototypes are broken down into several categories, but prototypes can simultaneously test for several design parameters.

- Conceptual Models. Consider them to be incomplete representations of the product. Concept prototypes depict how a part or product appears in a physical environment. They are frequently straightforward replicas built from readily available materials and inexpensive manufacturing techniques. This can take the form of a 3D-printed model or a cardboard cutout.

- Form Prototypes. These prototypes are constructed nearly or exactly to the size of the final product. They are frequently produced using techniques like CNC machining or 3D printing, and they provide designers with concepts for feature placement, size, proportions, and geometry to assist establish design parameters. Although form and fit prototypes are frequently integrated, form in particular may not be as concerned with surface finishes and precise GD&T.

- Fit Prototypes. These are trickier than idea and form since they employ the same or a related technique as the finished item, which is crucial to ensuring that it has the correct tolerance, clearance, and surface quality to work with other parts. These prototypes will assist the designer in determining the optimum manufacturing design and the most practical production procedures.

- Functional Prototypes. These and proof-of-concept prototypes cross across. However, engineering prototypes, which are frequently the kind that designers might utilize in testing and validating before producing the product, are grouped in with the majority of functional prototypes.

in the left: Prototype project for a robot competition

Tips for Speeding Up the Prototyping Process and Getting to the Product

- If final parts will be molded, design for injection molding when prototyping with 3D printing.

- Use aluminum tooling for end-use components, bridge production, and prototype. You can support production and speed up development without spending more money on more expensive steel tools thanks to aluminum tooling.

- If you comprehend the value and quantity required, 3D printing can make sense for prototypes and final products.

The way businesses approach product development can alter with the help of technology and a strong, knowledgeable staff. Hardware design is being disrupted by producers that offer expertise, rapid prototyping, and low-volume production. Startups, small businesses, and makers now have access to the same technology and expertise as their more established rivals.