Metal-Projects | Production | How To Cut CNC Machined Parts Prices

Share

Due to its great accuracy, precision, speed, and efficiency, CNC machining is frequently used in a variety of industries. However, compared to alternative production processes like 3D printing, CNC machining services may also be a little more expensive. Cost must be taken into account when using CNC machining for small-batch or mass production. This article lists 10 suggestions that will help you considerably reduce the price of your CNC-machined products.

What Affects CNC Machining Prices

Understanding the variables that affect machining costs in the first place is crucial before attempting to reduce them. The four basic factors affect the cost of CNC manufacturing.

- Costs associated with setup include everything from creating CAD and CAM files to scheduling processes. Setup expenses are fixed and have a greater impact on low production quantities.

- Material costs: The cost of the material from which a part is to be manufactured significantly affects the overall cost of the manufacturing process and the cost of the finished part. Rare materials drive up cost immensely. Machinability is also another material cost factor as it influences resource consumption and machining time and effort.

- Time is money in the realm of CNC machining, so to speak. Time spent on machining is a big cost-driver. The cost of machining a part increases with the amount of time required. As machining time grows, so do the expenses associated with operating and maintaining the CNC machine, energy use, and operator salaries.

- Miscellaneous costs: These expenses in CNC machining include anything that might be regarded as extra or exceptional. These consist of precise tolerances, specialized equipment, enhanced quality assurance, and slower machining speeds.

Ten Strategies to Lower the Price of a CNC Machined Part

There are three main strategies to reduce the cost of CNC machining when the main influencing elements are examined. Design optimisation is the most crucial of these, followed by material choice and special considerations. The ten methods listed below will help you cut your CNC machining costs dramatically.

1. Materials Selected

Make sure the material you choose has all the necessary features for your application and is the least expensive alternative before making a decision. Although material quality shouldn't be sacrificed, not every one of a material's qualities is required for every application. For instance, using heat-resistant steel to machine a whistle would be a wasteful and expensive choice.

Machinability of a material is a crucial factor. When possible, one should choose materials with good machinability, such as aluminum. The cost of various aluminum alloys varies as well. For instance, a part below constructed of the more expensive aluminum 3.1645 would cost 25% more than one made of aluminum 3.3206.

2. Avoid multiple finishes

A acceptable as-machined surface finish is often achieved using CNC machining. When possible, choose this finish because applying numerous surface finishes is more expensive even though they are required for some areas. Anodizing and Chem film, which enhance the surface, should only be requested when absolutely essential. Applying different surface treatments to different parts of an item is another significant cost-driver. Applying a Chem coating in one area while bead blasting in another is an illustration of this. Try to keep all finishing requirements consistent over the whole portion.

3. Order in bulk

In CNC machining, economies of scale play a vital role. As manufacturing volume rises, machining costs exponentially decrease. To provide context for the cost savings. The component shown in the figure below has a unit price of €50.57. With a manufacturing level of 10 pieces, the price per unit falls to €26.77, and with a volume of 100 parts, it falls to €16.88. These savings result from the setup cost remaining constant regardless of whether you produce one unit or one hundred units of the same part. Bulk purchases also save money on machine setups because the same settings are applied throughout the whole production process. Always order in bulk to take advantage of economies of scale.

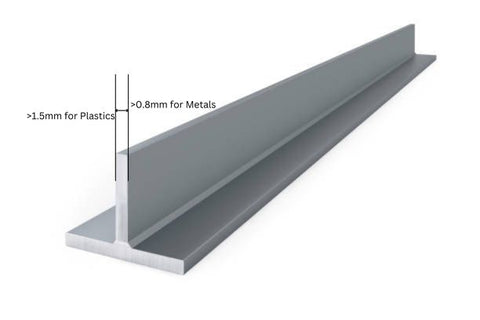

4. Steer clear of overly thin walls

Making thin walls requires more time. This is due to the fact that they are delicate and call for numerous low-depth cuts. They are also very inclined to vibrate, making it difficult and time-consuming to machine them to the required tolerances. As a result, machining takes longer and thus costs more. Create thicker walls to avoid paying this expense.

5. Internal Round Edges with Enough Radius

Perfect 90° internal corners cannot be machined because cutting tools are cylindrical. The only way to accomplish this is by EDM, a production technique that is far more expensive than CNC machining. All internal edges in your design should be rounded; doing so will cut down on the time it takes the cutting room to try to manufacture sharp edges. Additionally, we advise that the radius be at least 1/3 the cavity's depth in size. Due to the fact that small tools cannot remove large amounts of material in a single pass, multiple passes at slower speeds will be necessary, which will lengthen the machining process and raise the cost.

6. Avoid Creating Deep Cavities

Deep pockets and cavities take a long time to make since so much material must be removed. In addition, machining them may cause tools to hang, deflect, or break. Stepping down the end mill is the only way to prevent these tool issues. But it takes a lot of time to do this.

Designing cavities with a maximum depth that is four times their breadth will easily prevent all of these problems. For instance, a hollow that is 10 mm wide shouldn't be deeper than 40 mm. Keep in mind that a hollow is said to be deep if it is deeper than six times the cutting tool's diameter.

7. Limit the Thread Depth

Threads offer incredibly durable connections. Long threads are unnecessary because the strong thread connections appear in the first few threads. Long threaded holes could call for specialized equipment and take longer and more work to manufacture. Never go deeper than three times the diameter of the hole with threads. We advise including an unthreaded length of at least half the hole diameter at the bottom of the hole when threading a blind hole.

8. Avoid tight tolerances and only specify tolerances when necessary.

Tolerances should only be stated when necessary because they often increase machining costs and time. In cases when special tolerances are not specified in the design, CNC machines are incredibly exact and create standard tolerances. Since they are difficult to implement, tight tolerances should only be set when absolutely essential. Additionally, they need extra manual inspections and machining time. Additionally, we advise you to use GD & T, which specifies looser tolerances, in your drawings.

9. Use regular hole sizes

Use common drill bit sizes when creating holes. End mills would be needed to complete the slope to the specified non-standard dimension for non-standard hole diameters, thus lengthening the machining process.

10. Exclude letters from the machined design.

Machining messages on components adds unneeded expense and takes more time and labor to produce. After production, required writing can be painted on the finished component. Engraved texts should be used if it's vital to include text because they require less material removal.

Conclusion

You can considerably lower the price of CNC machined parts by implementing these suggestions. At Metal-Projects, we provide quick, reasonably priced, and dependable CNC machining services, whether for small or large scale projects. Upload your optimized models and choose the best materials for your application on the fast quoting platform.