Utilizing EDM to Scale Metal Additive Manufacturing Quickly

Share

Over the past ten years, additive manufacturing (AM) for metals has experienced explosive growth, particularly in the direct metal laser sintering (DMLS) business, where almost every industry has found a use for additive manufacturing. These machines are used every day to produce prototypes, production parts, mold components, and unique custom parts that are only feasible with additive manufacturing.

Daily headlines tout the approval of new materials, the accomplishment of finer print details, and larger build sizes, but we hardly ever hear anything about the other post-processing aspect of metal additive manufacturing. De-powdering, heat treating, stress relieving, finish machining, polishing, and sometimes the most underrated of all—cutting pieces off the build plate—are topics that are rarely discussed.

Removing Printed Parts from Build Plates

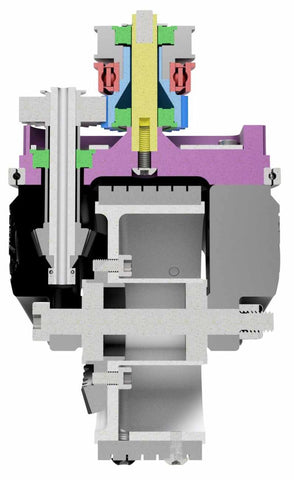

In the left we have final part following EDM cutting. The next step involves support structure removal.

Let's face it: Cutting off a build plate is one of the most tedious and underappreciated steps in the metal 3D printing process, but it's vitally necessary to get it right the first time in order to avoid incurring additional costs. This once-simple procedure has grown more difficult in recent years. Although printers are more quickly than ever, the materials they use to print the pieces in are becoming more difficult to remove from the construction platforms. The dimensions of a construction platform can occasionally be too large for commonly used cutoff techniques. We recognized this impending issue and started looking for a better alternative, which we found in the HB series molybdenum wire EDMs from EDM Performance Accessories. Electrical discharge machining, sometimes known as EDM, is also known as wire erosion, die sinking, spark machining, and wire burning. Using repeated sparks between the platform and the molybdenum wire in contact with a dielectric fluid, EDM erodes materials.

EDM Solves for Scale

We wanted to control capacity and be able to work with components as big as 31.5 in. by 15.75 in. by 19.69 in. with our partner's fleet of GE Additive Concept Laser M2s and the recent acquisition of two Concept Laser X Line 2000R printers (800mm by 400mm by 500mm). The HB800 EDM works with smaller builds while handling all three dimensions without any problems. Accuracy was another factor. Traditional bandsaws work well for our large-format aluminum parts, but they are not the best choice for cutting tougher Inconel pieces. The HB series EDM was able to complete test cutoffs of steel and Inconel materials at only 0.005 in thanks to molybdenum EDM technology. (0.127mm) off the build plate surface and cutting only a 0.008 in. (0.203mm) kerf or gap through the part.

Brass vs. Molybdenum Wire: Reducing Speed and Cost

We have to think about speed and price after size and capacity. Our objective is to offer customers quick-turn prototypes and finished products at costs that most small or large businesses can afford. We compared a conventionally difficult item on our old brass wire EDM machine and our new HB series EDM in order to gauge cutting speed. On this steel valve body, the brass EDM had a cutoff time of, on average, 7-8 hours. During cutting, the numerous little support components on this component could come away and cause wire breaks and delays. Its cut thickness varies greatly as well.These are not the best circumstances for effective EDM cutting. However, fast wire molybdenum EDM operates in a very different way than brass EDM. On the HB machine, the wire moves at over 40 feet (12.2 meters) per second, creating a "flushing" action through the part to quicken material removal. The wire's tensile strength is double that of brass EDM wire, and its melting point is approximately three times higher. These two characteristics enabled a completely error-proof cutoff with no speed loss or break delays. The molybdenum EDM ultimately reduced processing time by six hours.

Nevertheless, if a new technology won't immediately benefit customers, it makes no sense to invest in it. The molybdenum EDM is less expensive to buy, but because it operates more quickly and has fewer moving parts or pricey chillers, it also lowers the costs that are included in bids. In total, over the two years we've used these machines, process costs have been cut by 80–90% as a result of shortened cycle times and lower machine operating costs. These savings ultimately benefit the client.

Although separating metal components from their build plates is never simple, these EDM machines have shown to be quite efficient, especially when used in conjunction with our large-format GE Additive X Line printers.

Need custom 3D-printed parts? Access this link and Upload your CAD file for an instant online quote.