What to take into consideration for a metal structure building

Share

Building a metal structure necessitates careful thought and planning to ensure a safe and long-lasting end result. There are several important factors to consider when building even a fence, railing, industrial building, or any other metal project. Here are some of the most critical factors to consider when constructing a building metal structure.

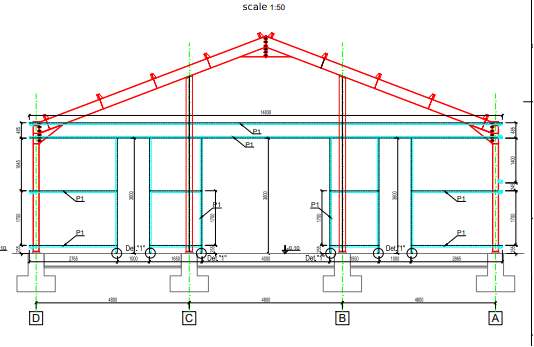

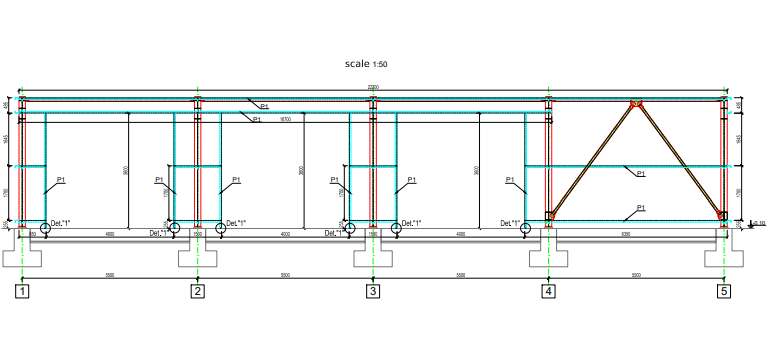

- Design and Fabrication

The design and fabrication of a metal structure is one of the first things to consider. Metal fabrication is the process of producing metal products in a factory setting by cutting, bending, and welding. You must work with a metal fabrication company that has the necessary skills and equipment to create the parts you require. The metal structure's design should be carefully considered as well to ensure that it is strong enough to withstand the intended use.

- Manufacture on Demand

Another important consideration is whether the metal parts should be manufactured on demand or in bulk. If you are constructing a large metal structure, manufacturing the parts in bulk may be more cost-effective. However, if you're working on a small metal project, it might be more practical to have the parts made on demand. This gives you more control over the manufacturing process and ensures that you get the parts you need when you need them. You can request a quote for your project on Manufacture-on-Demand page.

- Steel Quality

Another important factor to consider is the quality of steel used in the metal structure. Steels have different properties, such as strength, ductility, and corrosion resistance. Based on the intended use and environmental conditions, you must select the appropriate type of steel for your metal structure. For example, if you are constructing a metal structure in a coastal area, stainless steel may be required to prevent corrosion. You can read more on this subject here.

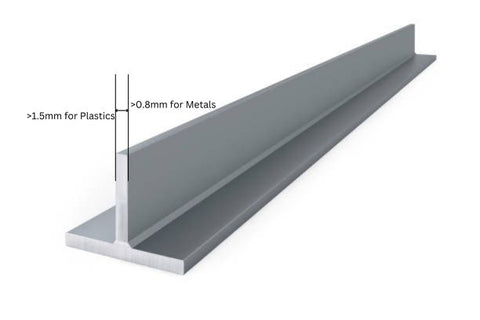

- Metal Cutting

Metal cutting is an important step in metal fabrication that must be done precisely to ensure that the metal parts fit together correctly. Metal cutting can be done in a variety of ways, including CNC (computer numerical control) cutting and laser cutting. Each method has benefits and drawbacks, and you must choose the best one for your metal project based on factors such as accuracy, speed, and cost.

- Welding

Welding is the process of joining metal parts and is an important step in metal fabrication. TIG (tungsten inert gas) welding, MIG (metal inert gas) welding, and stick welding are all types of welding. You must select the appropriate welding method for your metal structure based on factors such as strength, speed, and cost. Or let a professional team deal with it.

- Surface Treatment

After constructing the metal structure, you may wish to consider surface treatment to improve its appearance and durability. Painting, powder coating, and galvanizing are all surface treatment options. The surface treatment for your metal structure should be chosen based on factors such as intended use, environmental conditions, and desired appearance.

- Installation

Finally, think about how the metal structure will be installed. If you are constructing a large metal structure, you may need to hire a professional installation company to ensure proper installation. You may be able to install smaller metal projects yourself or with the assistance of friends and family.

We, at Metal-Projects, can help you go through the entire process. Contact us and let us now what are your questions. What are your plans and what is your budget. With our network of over 150 manufacturers, surely will find you one professional to do it for you.

To summarize, constructing a metal structure necessitates careful thought and planning. Consider design and fabrication, on-demand manufacturing, steel quality, metal cutting, welding, surface treatment, and installation. By considering these factors, you can ensure that your metal structure is safe, durable, and long-lasting.